Productio Processus O et Inspectionis Flow

Cum supra 9000 operariorum peritissimi et 293 productorum productorum linearum per 13 officinas diffusae, viginti milia talentorum fistulae ferreae in 2022 egimus, et venditio copia ultra 160 decies centena millia US pupa anno 2018. Ad 17 annos continuos Youfa inter TOP inscribitur. 500 conatibus in Sinis Vestibulum Industriis cum 2006.

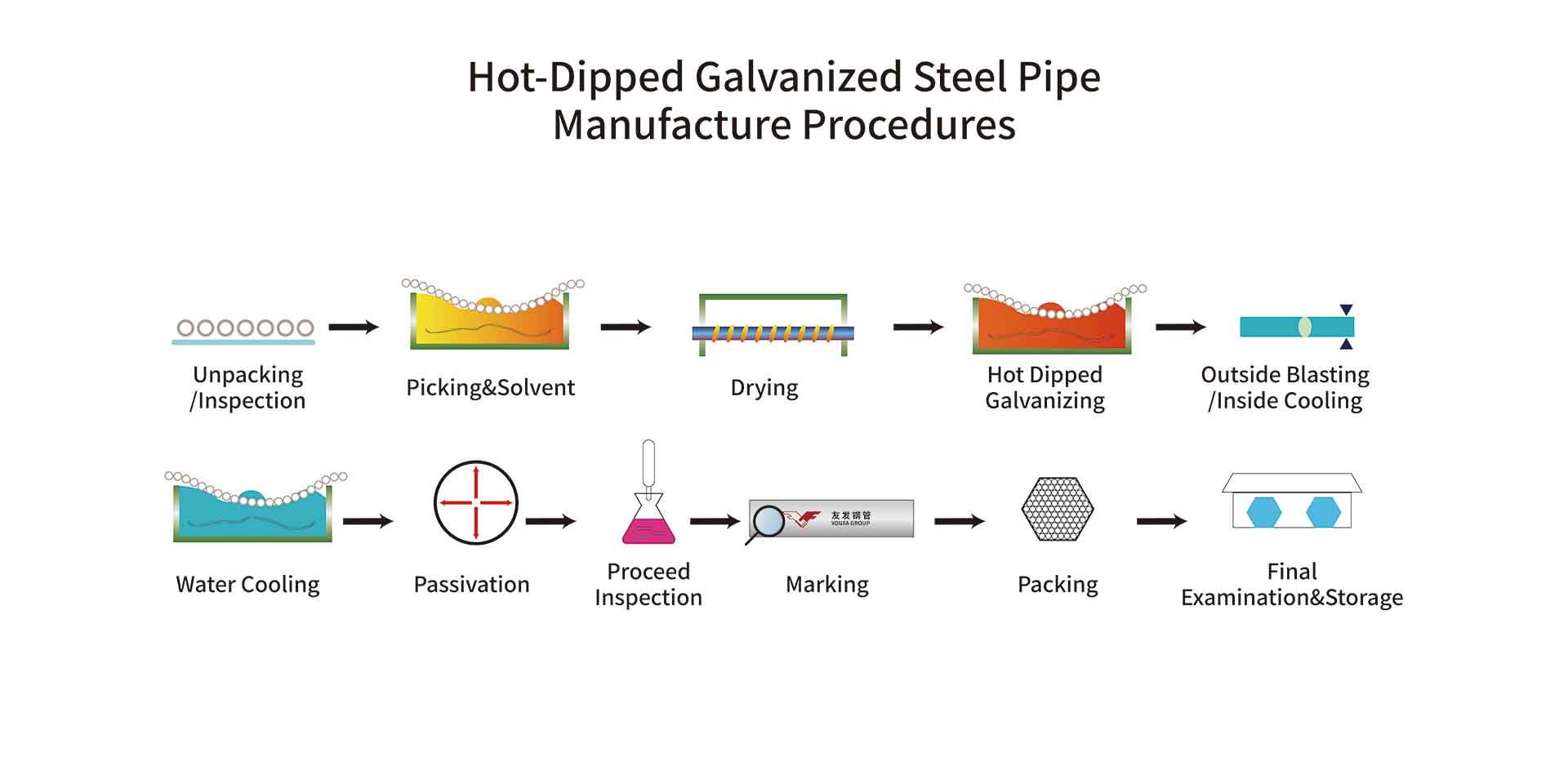

Calida intincta Galvanized Ferro Pipe

Procedendi fabricare

. 11.Final examen & at

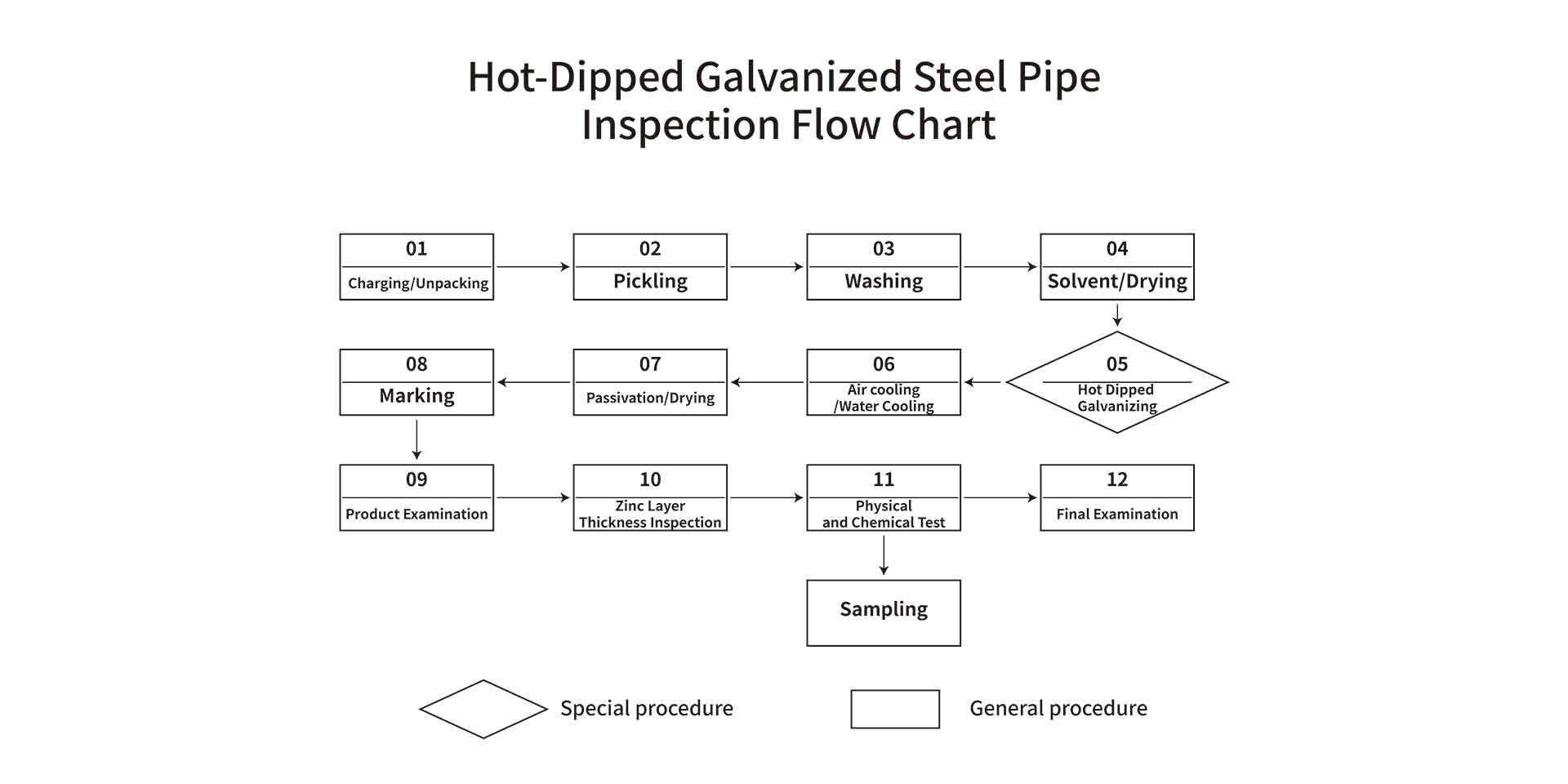

Calida intincta Galvanized Ferro Pipe

O chart inspectionem

01.Charging / Unpacking → 02.Pickling → 03.Washing → 04. Solvent / Siccatio → 05.Hot tincta moveret → 06.Air refrigerationem / Aqua refrigerationem → 07.Passivation / Siccatio → 08. Marking → 09.Product examen → X .Zinc accumsan crassitiem inspectionem → 11. Physica et chemica test → 12.Final examen

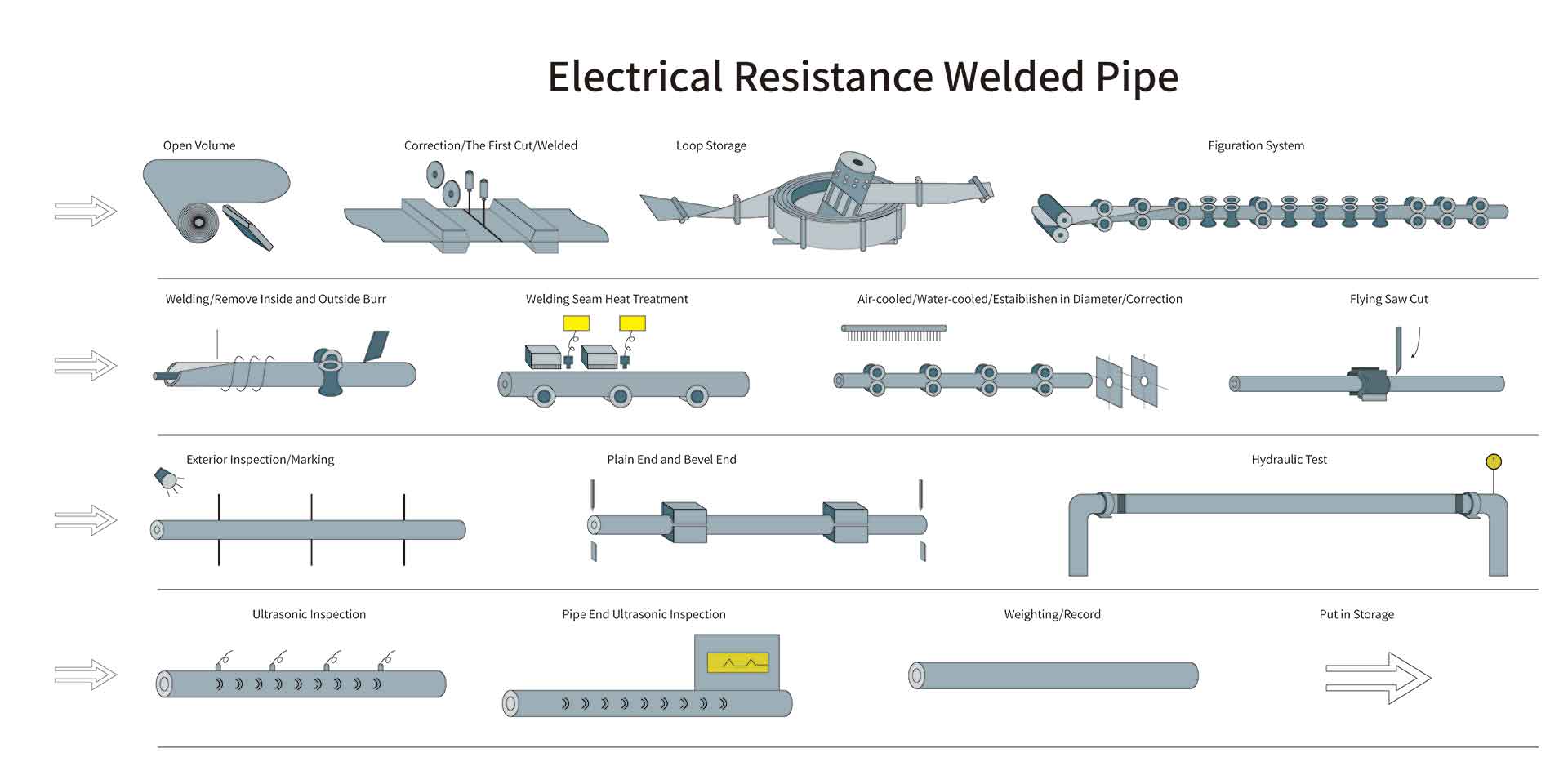

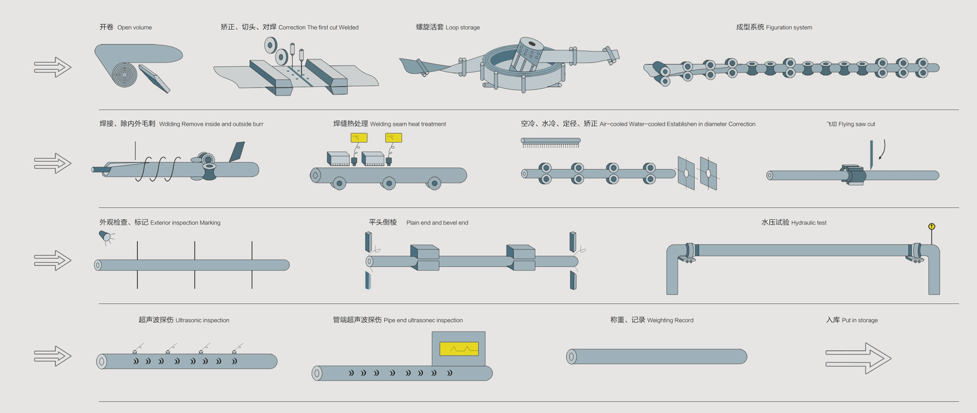

Electrical Resistentia Weld Pipe-ERW

Procedendi fabricare

01.Open volubilis → 02.Correction/Prima incisa/iuncta → 03.Loop repono → 04.Figuration system → 05.Welding/ Aufer intra et extra lappa → 06.Welding commissura caloris curatio → 07.Air refrigeratum / Water- Refrigerant / Estaiblishen in diametro / Correctio → 08.Flying videns incisam → 09. Exterior inspectio / Vestigium → 10. Plane finis , et finis → 11. Hydraulic test → 12. Ultrasonica inspectio → 13. Pipe finis ultrasonicae inspectionis → 14.Weighting/ Record → 15.Put in repono

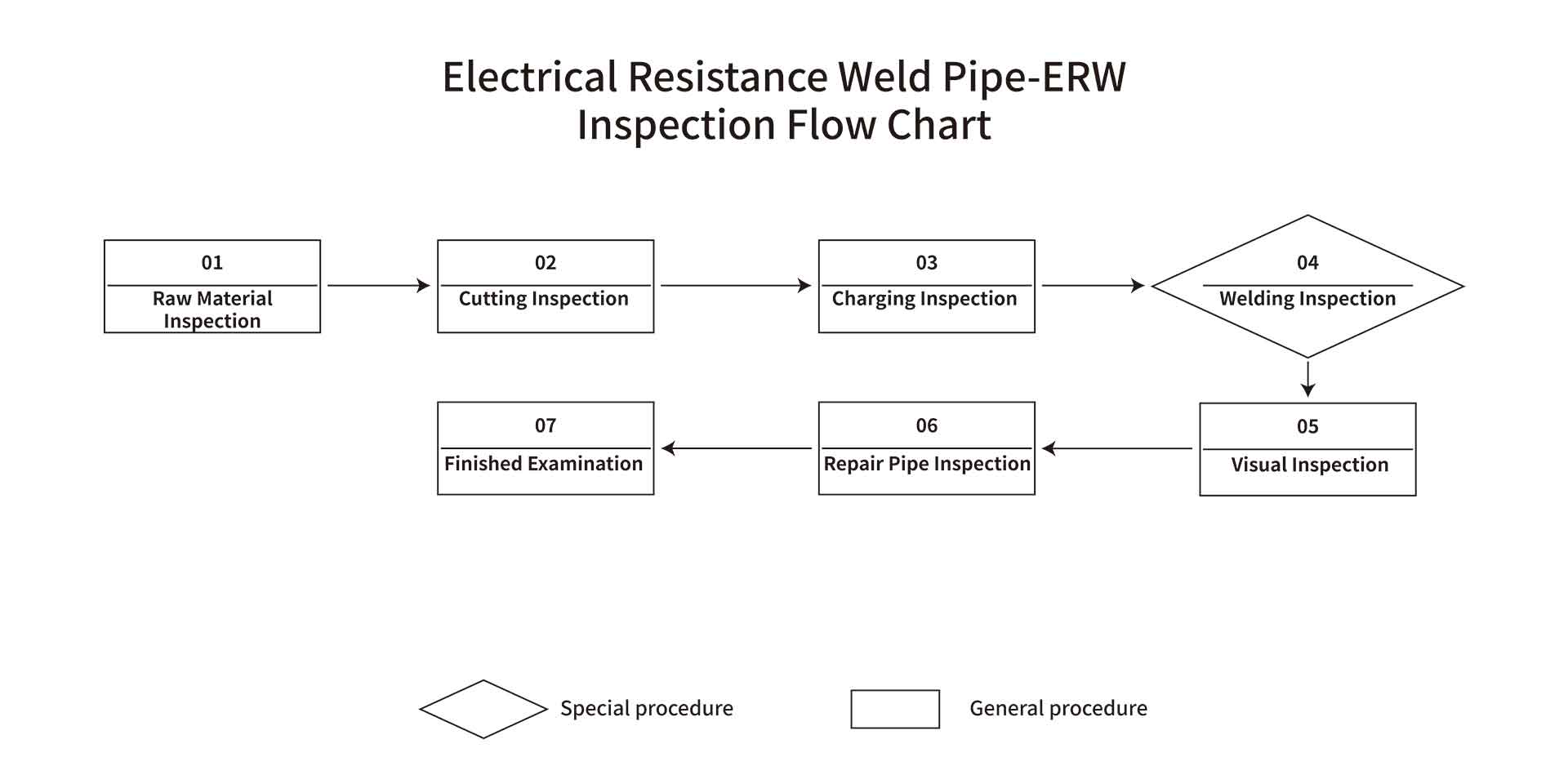

Electrical Resistentia Weld Pipe-ERW

O chart inspectionem

01. Rudis materialis inspectionis → 02.Cutting inspectionem → 03.Charging inspectionem → 04.Welding inspectionem → 05. Visual inspectionis → 06.Repair pipe inspectionem → 07.Finished examen

Rudes materiae et processuum productionis probabimus secundum diversa signa, ut producta signa conveniant vel exigentias contractus.

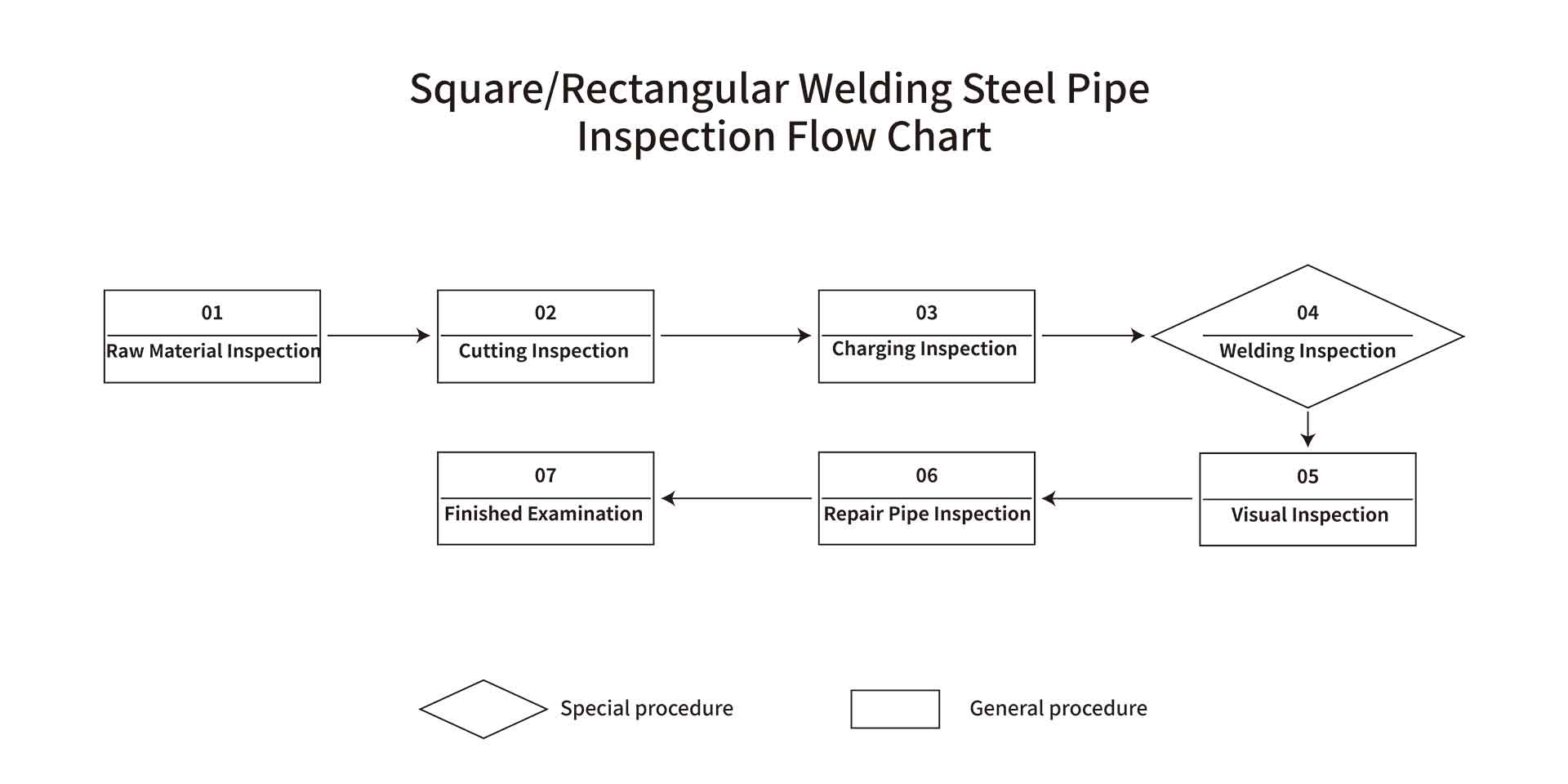

Quadratus/rectangularis Welding Steel Pipe

O chart inspectionem

01. Rudis materialis inspectionis → 02.Cutting inspectionem → 03.Charging inspectionem → 04.Welding inspectionem → 05. Visual inspectionis → 06.Repair pipe inspectionem → 07.Finished examen

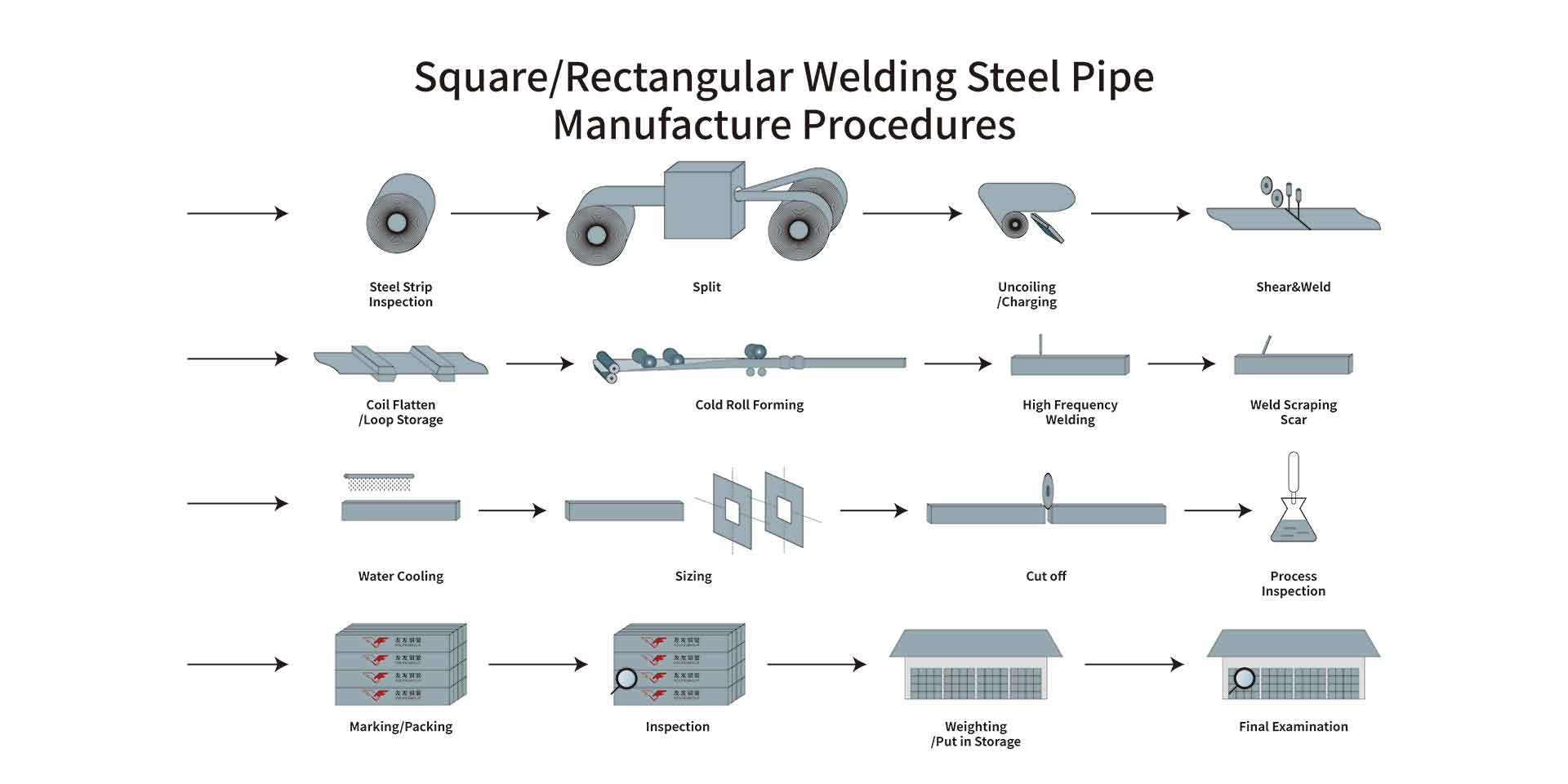

Quadratus/rectangularis Welding Steel Pipe

Procedendi fabricare

01. Ferro habena inspicienda → 02.Split → 03.Uncoiling / praecipiens → 04.Shear & Weld → 05. Coil Flatten / Loop repono → 06.Cold volumen formans → 07. Altitudo Frequentia glutino → 08.Weld radendo cicatricem → 09. Aqua refrigerationem → 10.Sizing → 11. abscinde → 12.Process inspectionem → 13.Marking / stipare → 14.Inspection → 15.Weighting / pone in repono → 16.Final examen

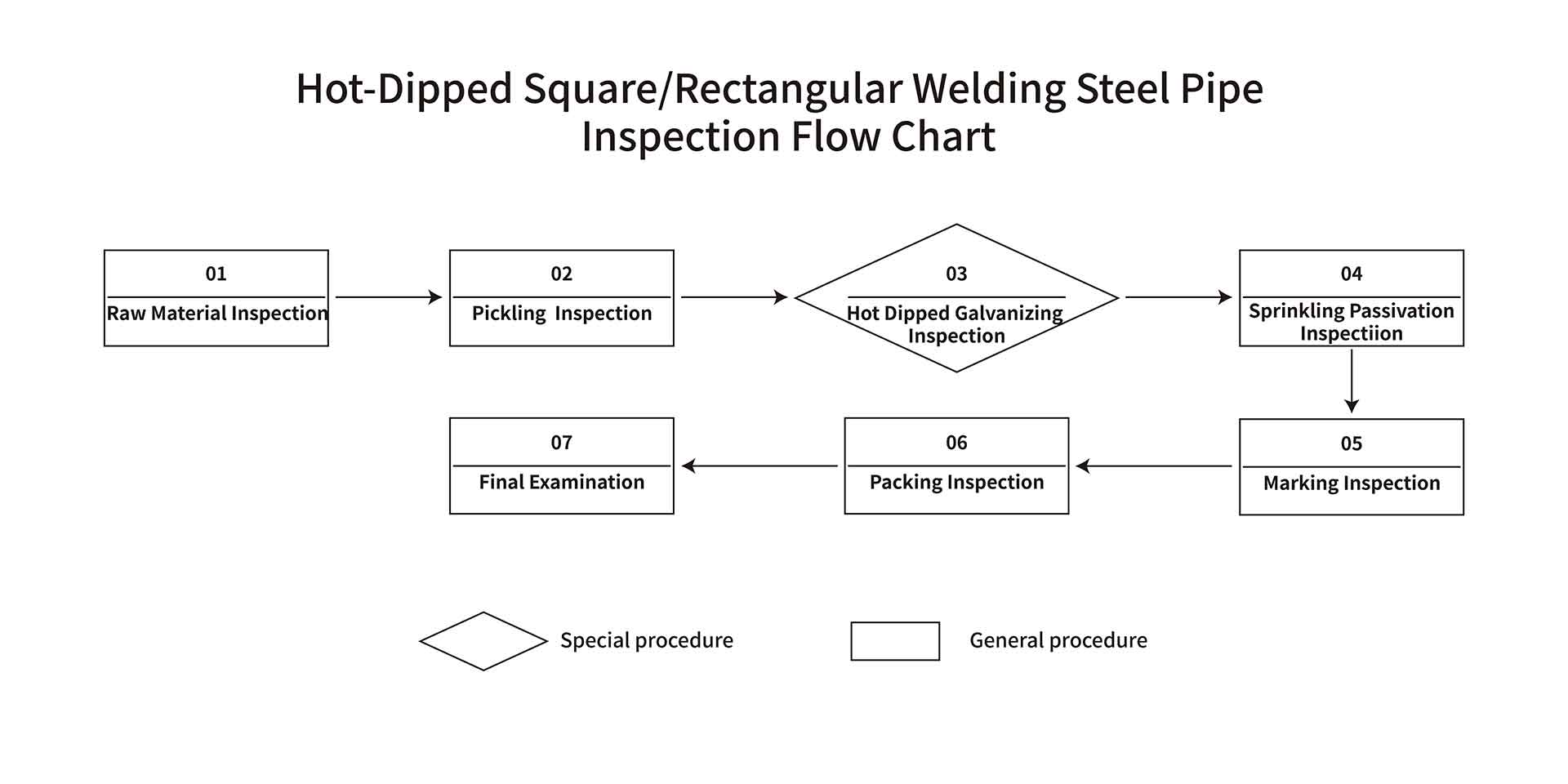

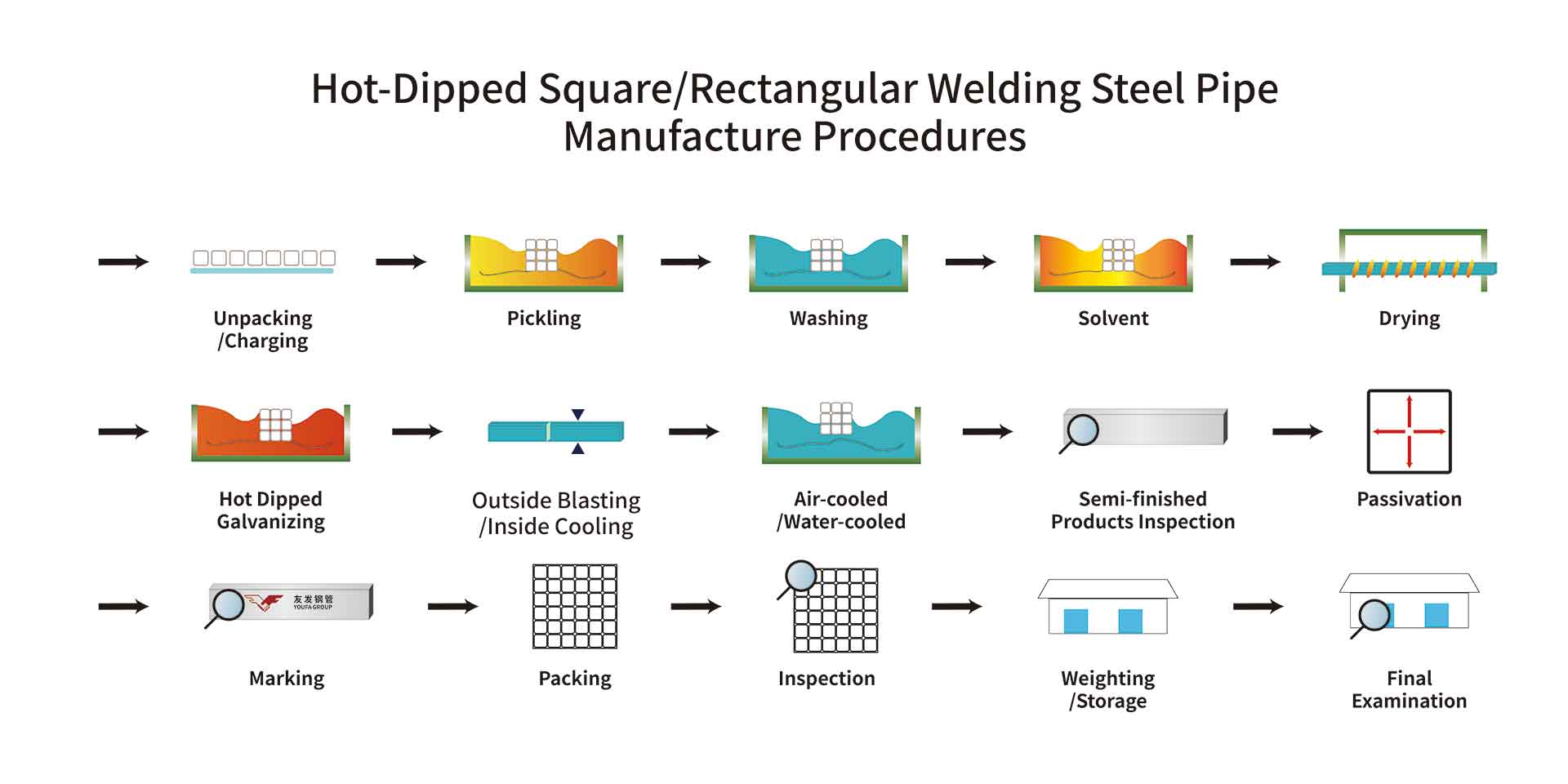

Hot-Dipped Square / Steel Pipe rectangularibus

O chart inspectionem

01. Raq materia inspectionis → 02.Pickling inspectionem → 03.Hot tincta Galvanizing inspectionem → 04. Sprinkling passionis inspectionem → 05. Marking inspectionem → 06.Packing inspectionem → 07.Final examen

Rudes materiae et processuum productionis probabimus secundum diversa signa, ut producta signa conveniant vel exigentias contractus.

Hot-Dipped Square / Steel Pipe rectangularibus

Procedendi fabricare

01.Welding ferro tibia → 02.Unpacking / praecipiens → 03.Pickling → 04. Lavacrum → 05. Solvendo → 06. Siccatio → 07.Hot intincta Galvanizing → 08.Outside adflatu → 09.Inside Refrigerant → 10. Air refrigeratum / Aqua refrigeratum → 11. Semi- perfecta products inspectionem → 12.Passivation → 13. Marking → 14. Packing → 15. Inspectio → 16.Weighting / at → 17.Final Examen

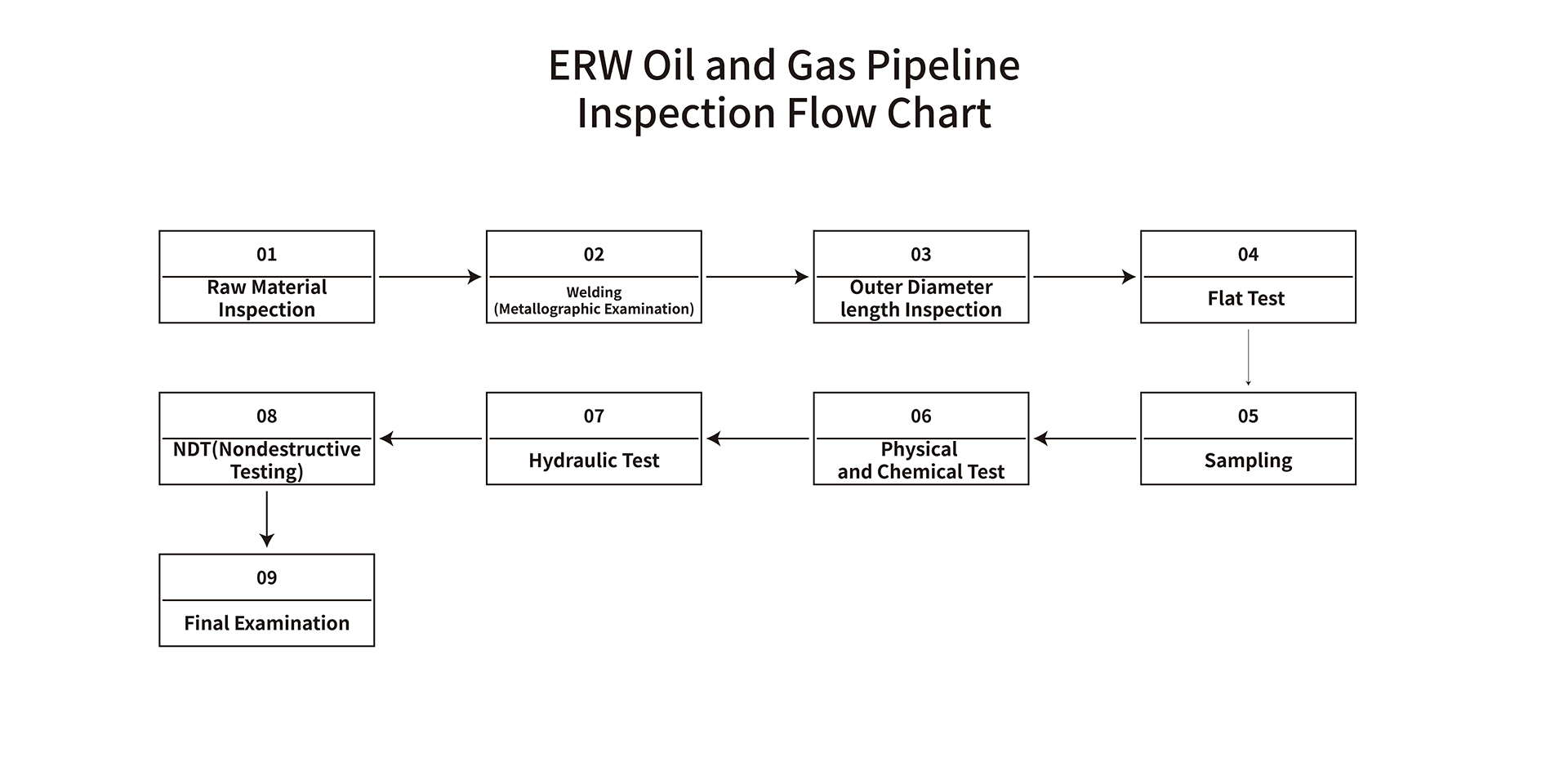

ERW oleum et gas pipeline

O chart inspectionem

01. Rudis materialis inspectio → 02.Welding (examen metalligraphicum) → 03. Examen diametri longitudinis →4.Flat test →5.Sampling → 06.Physical et chemica test → 07. 09.Final Examen

Rudes materiae et processuum productionis probabimus secundum diversa signa, ut producta signa conveniant vel exigentias contractus.

01.Open volubilis → 02.Correction/Prima incisa/iuncta → 03.Loop repono → 04.Figuration system → 05.Welding/ Aufer intra et extra lappa → 06.Welding commissura caloris curatio → 07.Air refrigeratum / Water- Refrigerant / Estaiblishen in diametro / Correctio → 08.Flying serra → 09. Exterior inspectio / Vestigium → 10. APlain finem et finem → 11.Hydraulic test → 12. Ultrasonica inspectio → 13. Pipe finis ultrasonicae inspectionis → 14.Weighting/ Record → 15.Put in repono

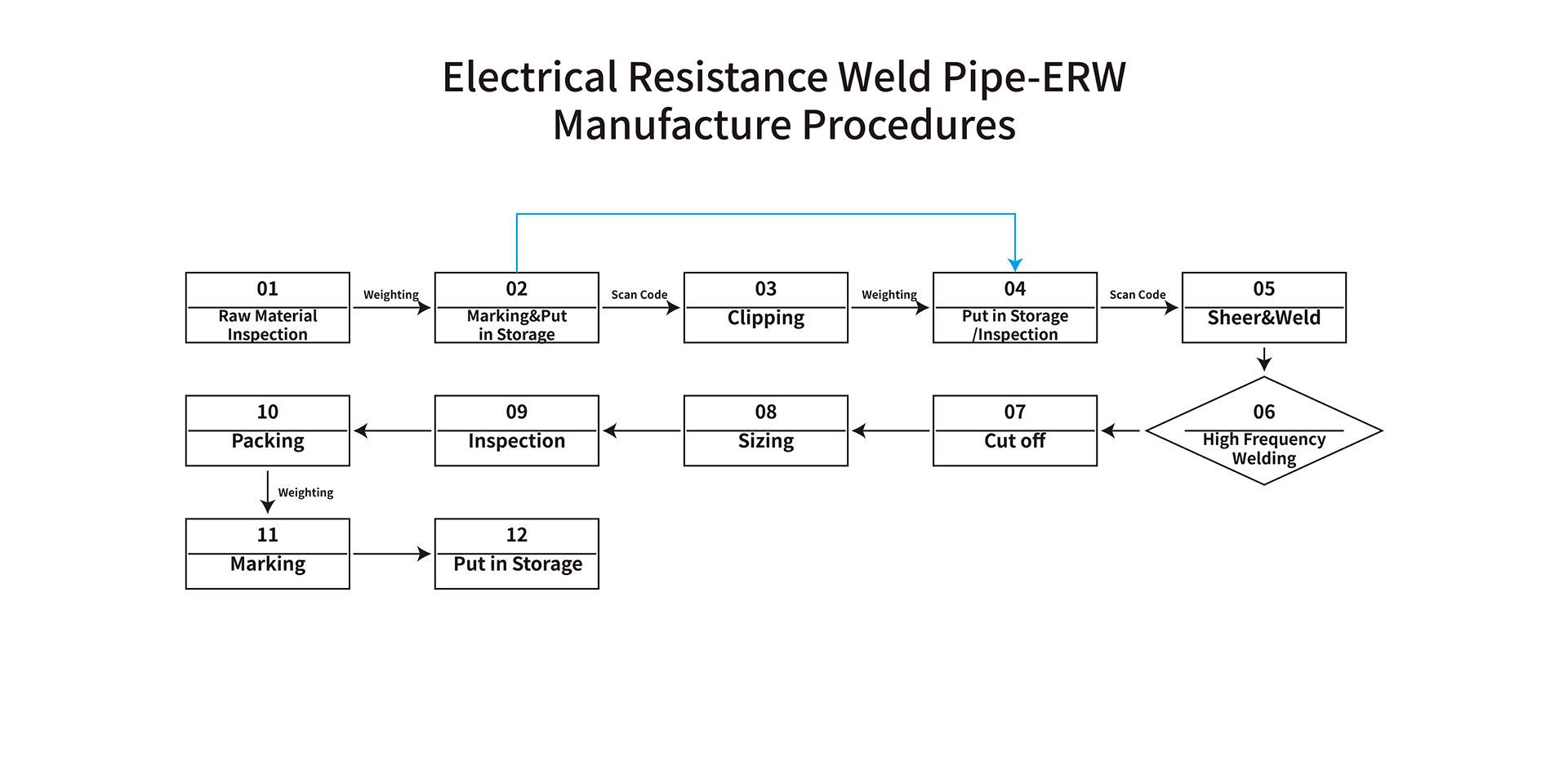

Electrical Resistentia Weld Pipe-ERW

Procedendi fabricare

01. Rudis materialis inspectio → 02. Marking & pone in reposita → 03. Declivia → 04. Pone in reposita / Inspectio → 5. Sheer & Weld → 06. Physica et chemica probatio → 07. Secare → 08. Sizing → 09. Inspectio → 10. 11.Weighting → 12.Scan codes →

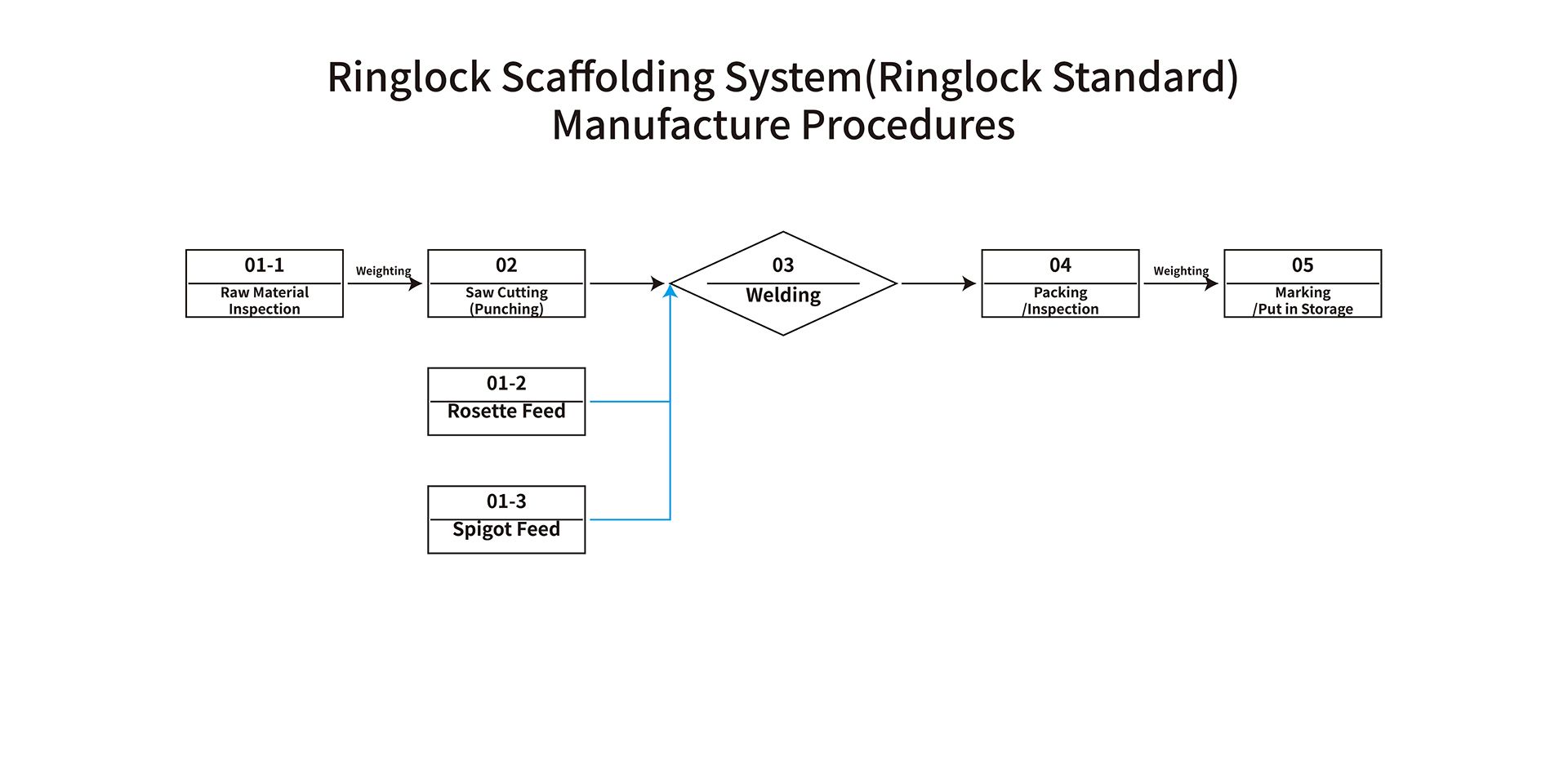

Ringlock Scaffolding System (Ringlock Standard)

Procedendi fabricare

01.Raw materialis inspectionis → 02.Saw sectionem (punching) / Rosette feed / Spigot feed → 03.Welding → 04.Packing/inspectionem → 05.Marking/ pone in repono

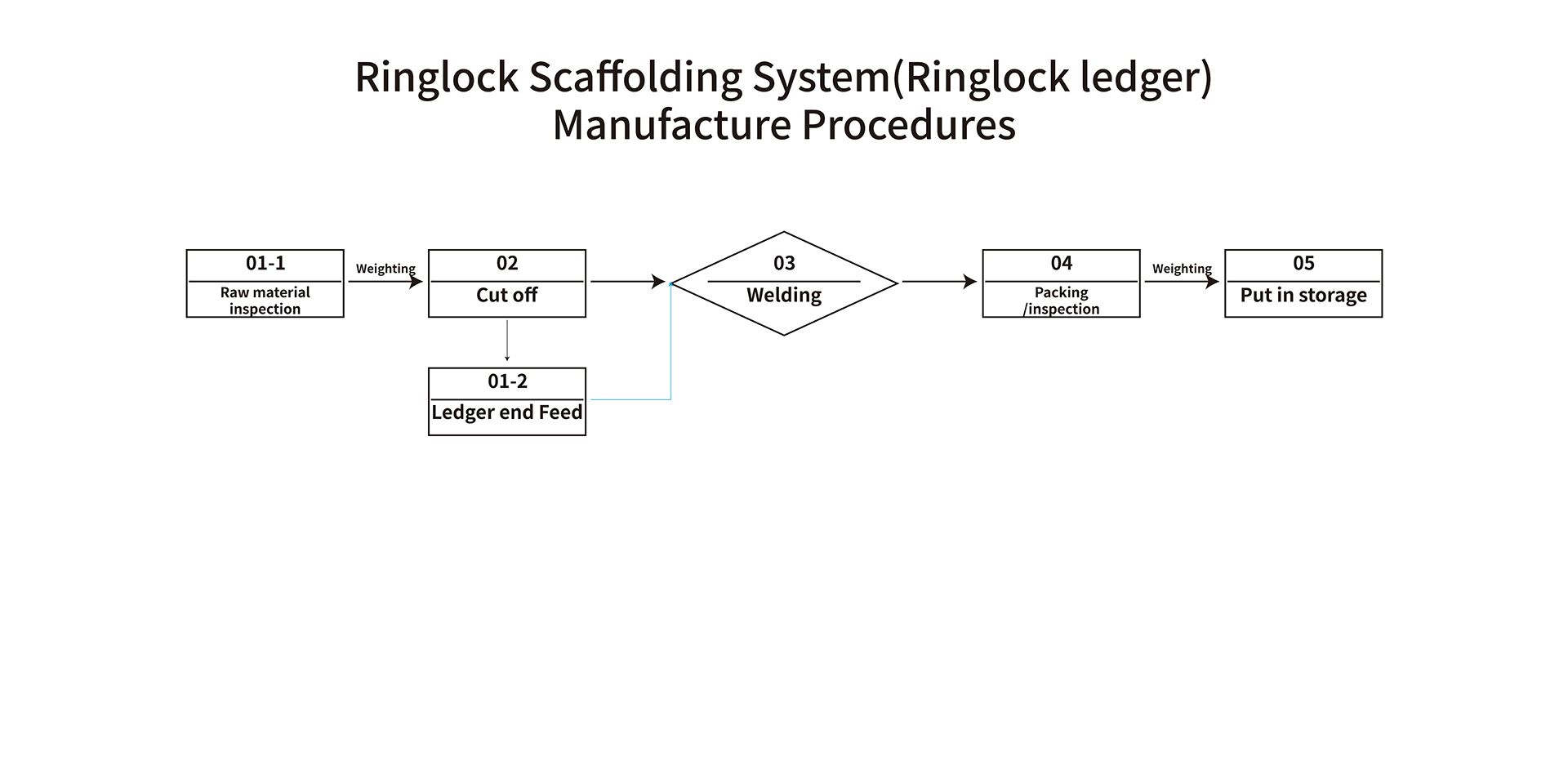

Ringlock Scaffolding System (Ringlock ledger)

Procedendi fabricare

01.Raw materialis inspectionem → 02.Cut off/Ledger finem pasce → 03.Welding → 04.Packing/inspectionis → 05.Marking/Pone in repono

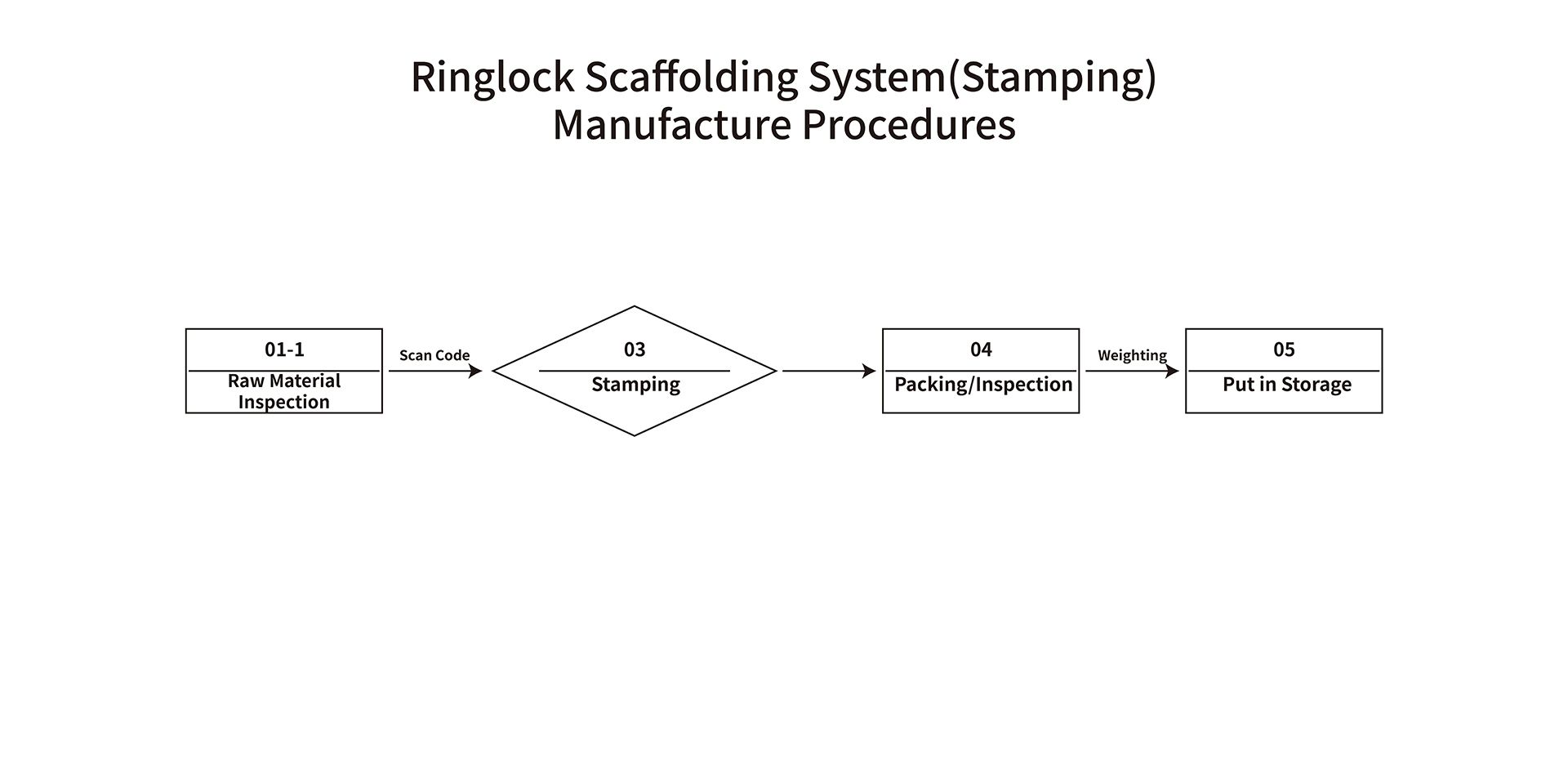

Ringlock Scaffolding System (Stamping)

Procedendi fabricare

01.Raw materia inspectionem → 02.Stamping → 03.Packing / Inspectionis → 04.Put in repono

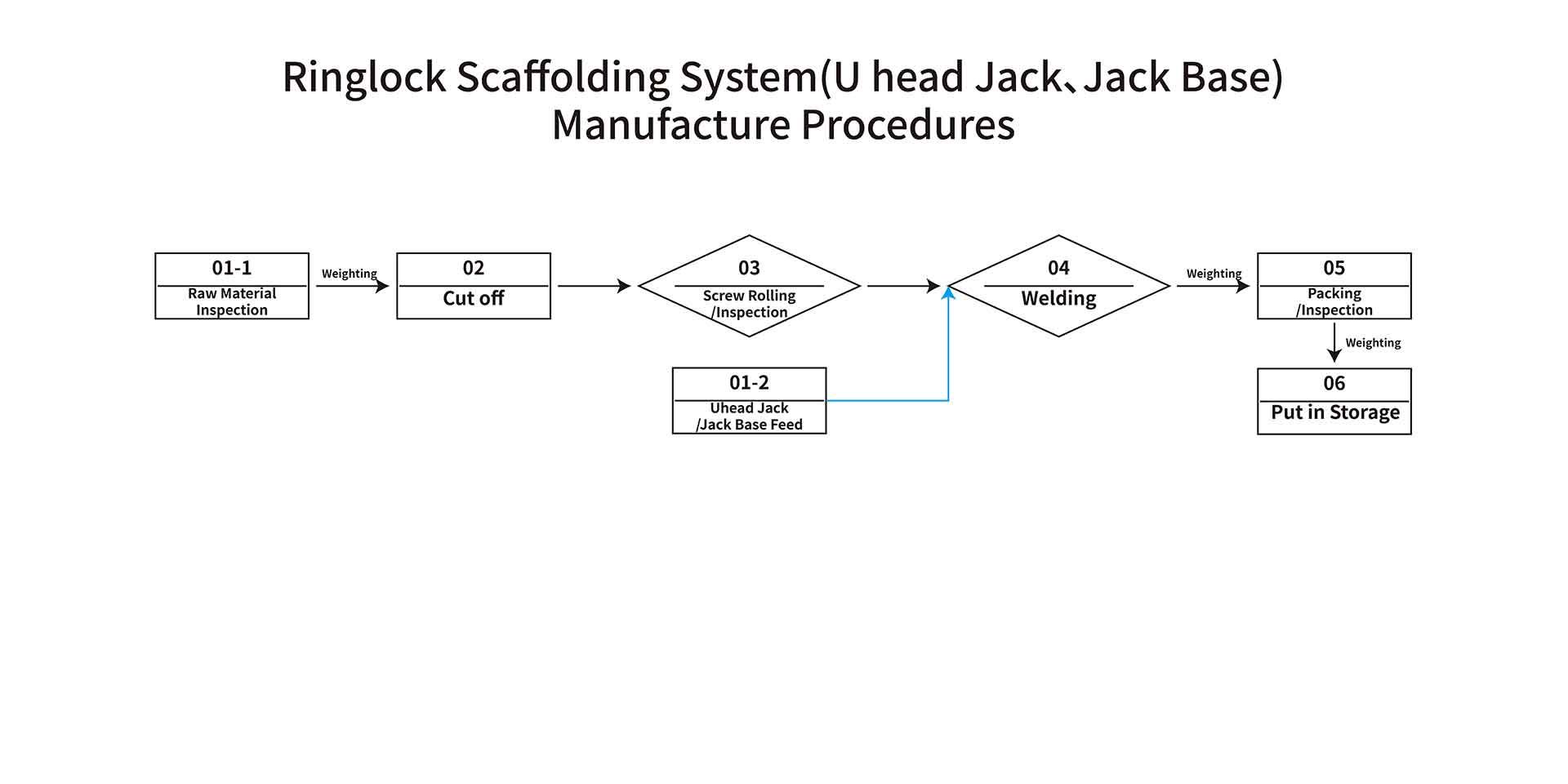

Ringlock Scaffolding System (U caput jack、Jack basi)

Procedendi fabricare

01.Raw materia inspectionis → 02.Cecidit → 03.Screw volubilem / Inspectionem / Uhead Jack / Jack basi feed → 04.Welding → 05.Packing/inspectionem → 06.Put in repono

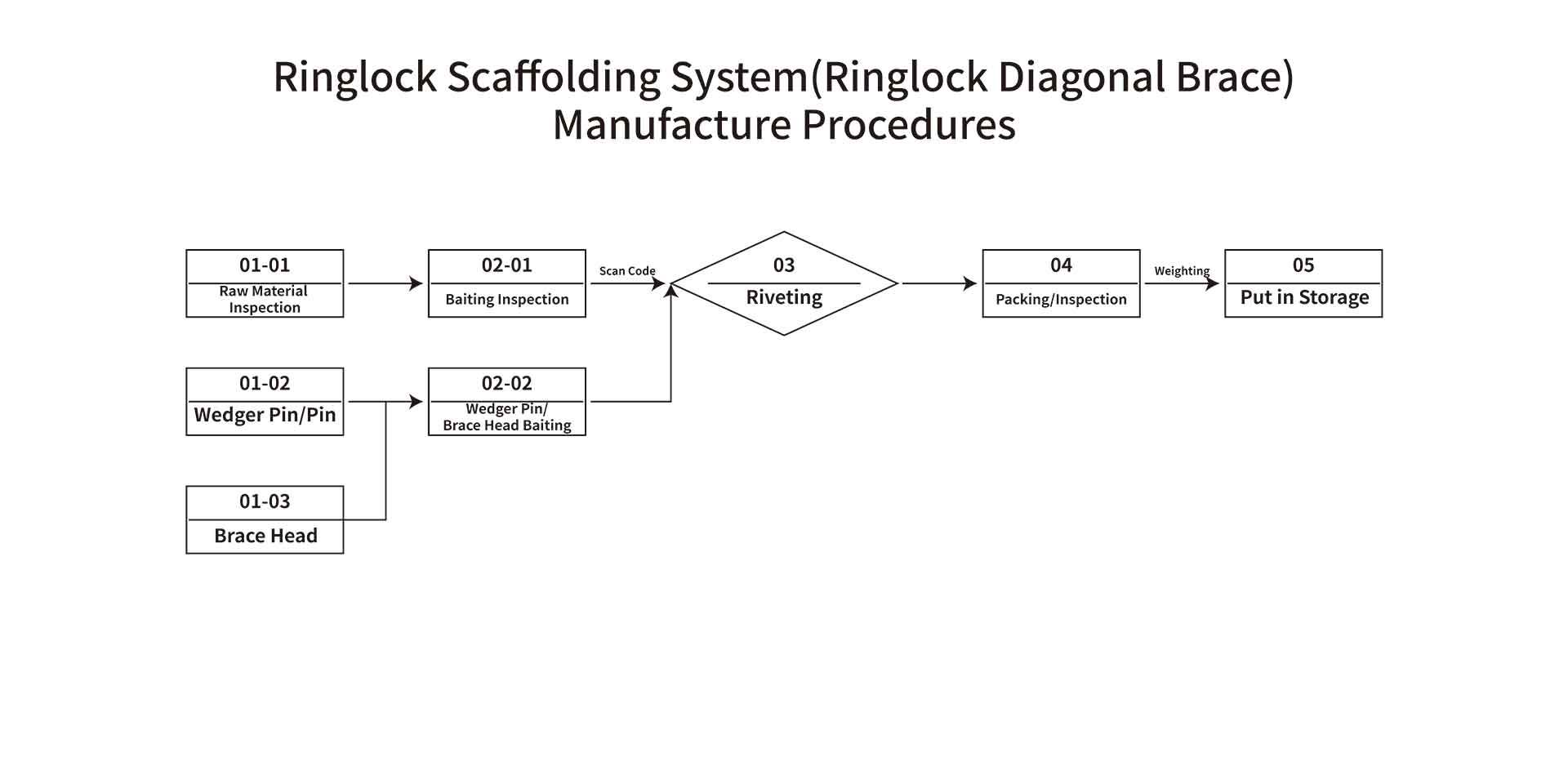

Ringlock Scaffolding System (Ringlock diagonalem ue)

Procedendi fabricare

01.Raw materialis inspectionem / Wedger clavum / Pin / Brac caput → 02.Baiting inspectionem / ora paxillus / Brac caput esca → 03.Welding → 04.Packing/inspectionem → 05.Put in repono